Because mixing in water storage tanks is a new concept, many people don’t realize that there are actually two different types of mixing: active mixing and passive mixing. Most state regulators don’t appreciate the difference either.

Passive mixing systems rely upon the inlet pressure to inject momentum into the tank to stir the water. Passive systems can consist of something as simple as a separated inlet and outlet. More complex (and costly) systems use a series of pipes and nozzles to squirt water in various directions in the tank.

Advocates of passive mixing systems like to claim that these systems are better because there are “no moving parts”. Unfortunately, that’s not the case. The pumps in your distribution system are the “moving parts” and the additional back-pressure exerted by the nozzles force those pumps to work harder (requiring more power and increasing maintenance costs).

Because passive mixing systems need a minimum amount of momentum to be effective, they lock an operator into required minimum turn-over rates that, in many cases, are more than the tank would otherwise experience. Instead of expanding the operational parameters under which a tank can be safely maintained, passive systems restrict operator options.

Passive systems involving multiple nozzles and piping can be very expensive to install, but the costs don’t end there. During repainting or maintenance, those pipes and nozzles require more time and labor to work around.

But the most important problem with passive systems is that they don't work very well. Passive mixing systems only are “on” when the tank is filling: once the inlet shuts off, the mixing is over – whether or not the tank chemistry (disinfectant residual) is homogeneous. When a tank becomes thermally stratified during hot sunny weather, the brief fill period is likely to be insufficient to homogenize the temperature within the tank. Plus, fill cycles occur typically during the night, when mixing is least needed.

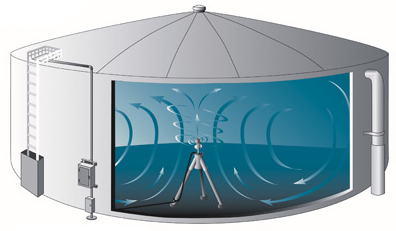

Active mixing systems use a motor to turn an impeller inside a tank and keep contents moving 24 hours a day, 7 days a week. Yes, active mixing systems have “moving parts” but their overall costs tend to be lower, and their maintenance requirements are minimal. Once installed, active mixing systems such as the PAX Water Mixer require no further operator intervention.

Active mixing systems use a motor to turn an impeller inside a tank and keep contents moving 24 hours a day, 7 days a week. Yes, active mixing systems have “moving parts” but their overall costs tend to be lower, and their maintenance requirements are minimal. Once installed, active mixing systems such as the PAX Water Mixer require no further operator intervention.

Operators can keep their tanks as full as they want and, even with low turn-over, the active mixer ensures that the entire volume of water is homogeneous and consistent in quality.

When it comes to mixing, you don’t want to be passive: get ACTIVE!

Interested in learning more about the operational benefits of active mixing? Attend our free webinar for Operators on May 20th.

We look forward to your comments and questions.

Sincerely,

Peter S. Fiske, Ph.D.

CEO, PAX Water Technologies