Onsite Sodium Hypochlorite Generation

A Cost-Effective and Resilient Alternative to Bulk Hypochlorite

By Robin Giguere, Ph.D., Principal Scientist

|

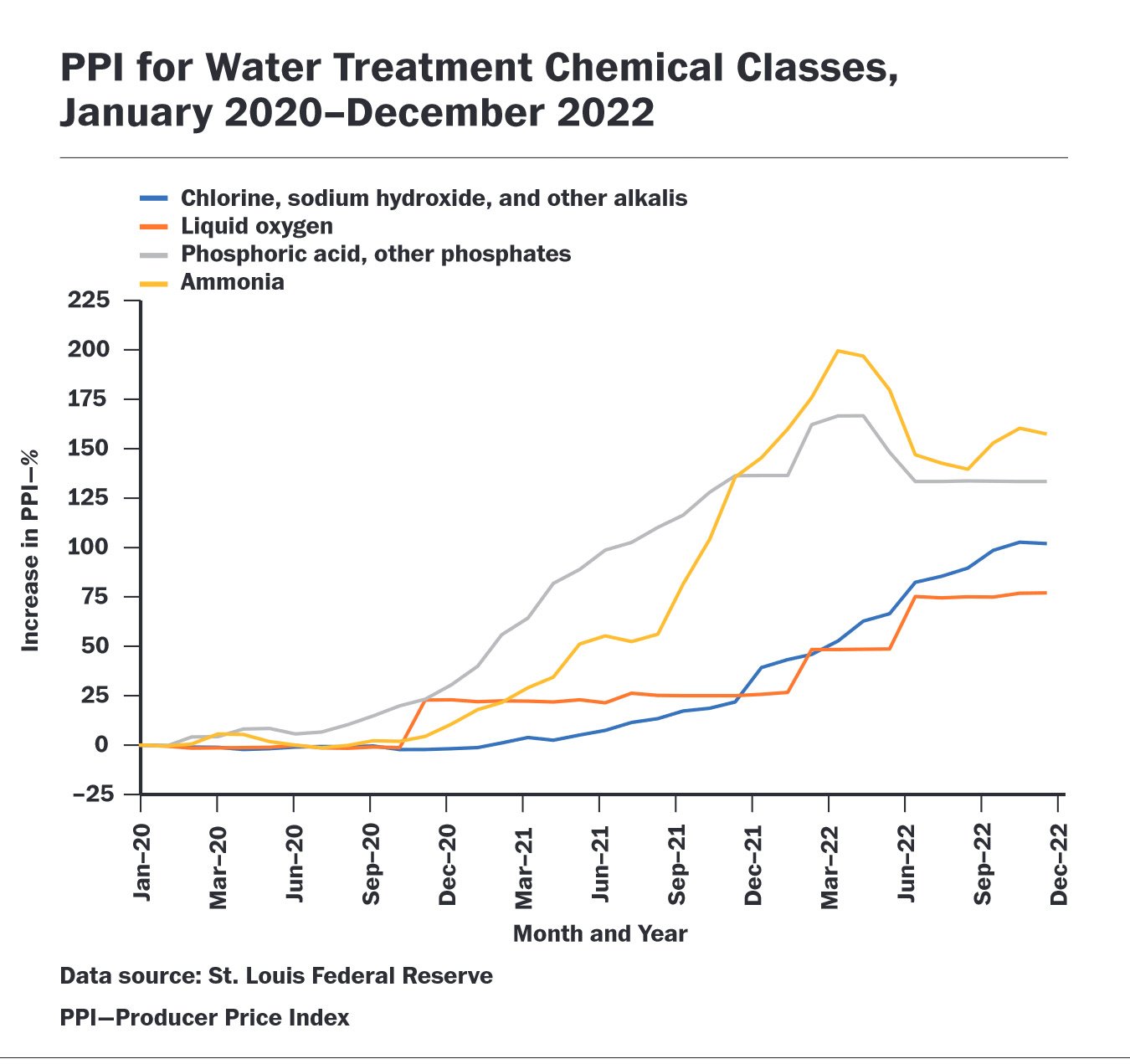

The ACE23 conference held in Toronto last year shed light on the growing concern over escalating prices of bulk sodium hypochlorite (commonly known as bleach). This issue has prompted a significant focus on adopting onsite generation technologies, such as Microclor®, as a reliable alternative for water utilities. A recent article featured in the AWWA Journal (May 2023) further emphasized challenges faced by the water industry due to supply chain disruptions and the rising prices of chemicals, reflected in the Producer Price Index (PPI). The authors discussed the strategic utilization of onsite generation to mitigate these disruptions and the resulting price shocks. |

|

Let’s expand on three key reasons why many utilities are embracing onsite generation of sodium hypochlorite (OSHG) as a cost-effective and resilient alternative to relying on unpredictable bulk deliveries.

- Stability of raw material prices for OSHG

Amidst the volatility observed in bulk sodium hypochlorite prices over the past few years, it is worth noting that prices of salt and electricity – the raw materials used in the production of sodium hypochlorite – have remained stable. By capitalizing on the use of these readily available materials, OSHG provides utilities with better control over inventory and financial planning.

- Limitations of Bulk Sodium Hypochlorite Storage

The storage of bulk sodium hypochlorite poses inherent limitations due to degradation over time, resulting in reduced effectiveness as a disinfectant. Moreover, the degradation process leads to the formation of undesirable by-products, such as chlorate and perchlorate. These limitations present challenges for utilities requiring large storage capacities or extended storage times, particularly if an increased supply is necessary for reliability. Conversely, salt, used in onsite generation, does not degrade, and can be stored in large quantities as needed.

- Challenges of Bulk Sodium Hypochlorite Deliveries

Bulk sodium hypochlorite deliveries present various challenges, encompassing risk and safety concerns as well as procurement and logistical issues. Given the current landscape of supply chain challenges, including truck driver shortages and rail service disruptions, relying on frequent and timely deliveries becomes less feasible. In contrast, utilities that use OSHG receive as few as one annual delivery of non-hazardous salt, streamlining procurement logistics and mitigating safety risks associated with hazardous chemical deliveries.